Some projects come together through efficiency. Others through conviction, trust, and a shared willingness to take risks. This one – as much as FANTOPLAST itself – belongs firmly to the latter. What began as one person’s desire to make good coffee accessible evolved into a deeply collaborative process between a coffee maker, two architects, and a group of designers finding their way through the hurdles of a newly founded business.

Two years after its doors first opened, I finally sat down and enjoyed a cup (actually two) at BEANDEPENDENT—the first project we ever billed as FANTOPLAST.

I immediately felt tucked in by the sounds of the operating coffee machine, the grinders, and the intense smell of roasted beans. Everything sounded and smelled familiar to the dedicated fan of the Italian espresso bar that I am. The thing is, I do enjoy a good coffee, yes—but I enjoy the experience that comes with it just as much, if not more. I could be alright—and Laurent will have to forgive me for saying this—with an average-tasting coffee if it is served in a delightful mix of visuals, sounds, and people seemingly present in the moment. In other words, there’s much more to a coffee place than just the coffee it serves.

At Laurent’s, excellent coffee is brewed in a space that moves beyond the Viennese coffee house tradition, while also steering clear of the nowadays familiar decor of plants, light wood, and warm lighting.

I sat together with Laurent, Peter, and Camilla, trying to trace back the steps that led to this minimalistic room where Laurent has made a home for his espresso bar and small roastery. It felt like meeting again with old school friends, and remembering those days when trial and error felt less like uncertainty and more like a shared belief that something would eventually come out of it.

This conversation has been edited and condensed for length and clarity.

Hey guys, could you all tell a bit who you are and what you do?

Laurent Since I commissioned the project, I'll start! My name is Laurent Pfeifer, and I'm the owner of BEANDEPENDENT. I'd been making coffee for about 12 years when I decided to scout locations for my own coffee place. I wanted a place with an artisanal approach to coffee making—focusing on the craft and the value chain behind it: the producers, the resources, all of that. I already knew how to make coffee and what equipment I wanted to make it with, so I started by looking for a location. Once I found it, that's where capeland came into play.

I've known Peter for a long time—he's an architect I trusted outside my family (I originally wanted to work with my brother!). I asked if he could create some renderings and provide a blueprint so I could build something myself to place my equipment and get the café going. He told Camilla—the other half of capeland—and together they offered to actually take on the entire project.

Capeland For us, it was an organic process. The constant conversation led us to share ideas within the office, and we naturally decided to take over the planning with the studio. We are Peter Kanzler and Camilla Struklec. After many years of working together, we founded capeland – Büro für Raum und Gestaltung in 2020. At capeland, we mostly focus on architectural reconstructions and renovations, but we also do furniture and interior design next to new construction projects. We work with reclaimed materials whenever possible—especially when new construction or new parts of a building are needed.

What does circularity mean in your work?

Capeland For us, circularity is a direction we want to take and follow through. It's about research, experimentation, and unlearning linear production concepts—finding new ways, new materials, new people to work with. In our day-to-day practice, it means working with simple structures that are put together in straightforward, sometimes modular ways. Working with clients who are aligned with this kind of thinking, starting small and growing bigger with time, it’s what we are aiming for.

The design we developed for this café is a good example. You can easily deconstruct it and use its parts independently. Of course, these kinds of design processes are more difficult in the building industry—in architecture at large. But we try to take these ideas to bigger scales too. It's part of our job to help others think about what might be circular, more sustainable, and more affordable in the long term—even if it looks more expensive on paper when you first see a cost breakdown. The main thing is that classic linear decisions are cheaper at this very moment, but in the long run they aren't. And they're not cheaper for our clients either. We need to convince them that circular materials are an expense worth making—because they'll prove cheaper in the long run, both for them and for the environment.

Laurent, do you think there is circularity in your work or in the way you work with coffee?

Laurent There is. Circularity in coffee is more present than ever. To me, it means connecting pieces—creating a circle from a chain, linking together all those open loops to create something whole. Each and every link in that chain is needed: from the origin of the coffee to where it's served or has been consumed. Ultimately it is about value and acknowledging that value. I want to make coffee, good coffee and make it accessible, because everybody deserves good coffee.

How do you think it's possible to make high-quality coffee more accessible? It's definitely a luxury not everyone can afford right now, and current trends aren't helping make it any cheaper…

Laurent Yeah, it is a luxury, but for the wrong reasons. I'm a one-person business, so I can afford to be more accessible—I have no salaries to pay. I still want the pupils from the school across the street to come get their cappuccinos here. I didn't have access to good quality coffee as a 15-year-old. We had to drink ourselves through a lot of bad stuff. To come back to your question: it's about not buying coffee everywhere it's sold. We don't need gas station coffee. I mean, it's convenient, but convenience is killing us. I would love to get rid of coffee-to-go cups because I find them disrespectful, to the taste and to what one is actually trying to create around coffee culture. The papery taste? Nobody out there really likes it. I charge 10 extra cents for to-go cups. And I don't offer single-shot espresso to-go. I won't do it, because 90% of the cups don't even leave the space. This is a Starbucks mentality, which is also the reason we have coffee shops like this one acting as counter-culture: they made coffee shops a global phenomenon. They took the Italian espresso bar, put it on steroids, capitalized it, and globalized it. And now we have cool shops because a few people said, no, we're not doing that Starbucks thing anymore. We're not putting syrups in. We're checking where our coffee comes from, and we're about taste, not just caffeine and added sugars.

Once the location was secured, the exciting moment came: how to furnish this big white empty room. How did you decide to bring us at FANTOPLAST on board?

Laurent When Peter and Camilla agreed to take on the project, I felt confident telling them I wanted a third wave café focused on quality, sustainability, and experience. It wasn't the easiest kind to design—the setup and tools are standardized, leaving little room for creativity. You have to follow a certain configuration. I also told them I didn't want any wood because I didn't like the idea of looking like many other coffee places that followed a Scandinavian aesthetic. And most importantly I told them: no blue.

Oh, I can see that—no blue at all. You're not colorblind or anything, right? Just making sure we're seeing the same thing.

Capeland Because Laurent was skating a lot, the main idea was to keep the space very clean and raw. Skateboarding materials—mainly concrete and steel—influenced our thinking. At the beginning, there wasn't much talk about specific materials. We focused on space design and the idea of having a big centerpiece for the bar, with every other element in the room as a satellite to that. I had met Raphael (FANTOPLAST co-founder) at some point, and he'd given me some samples. We thought we could give the material a try. When we proposed it to Laurent, he instantly liked the idea because it did fit the direction we both wanted to take with this project. We had decided to make a steel frame with PS Architekten in Graz – a studio we often work with for these kind of constructions as they specialize in metal work.

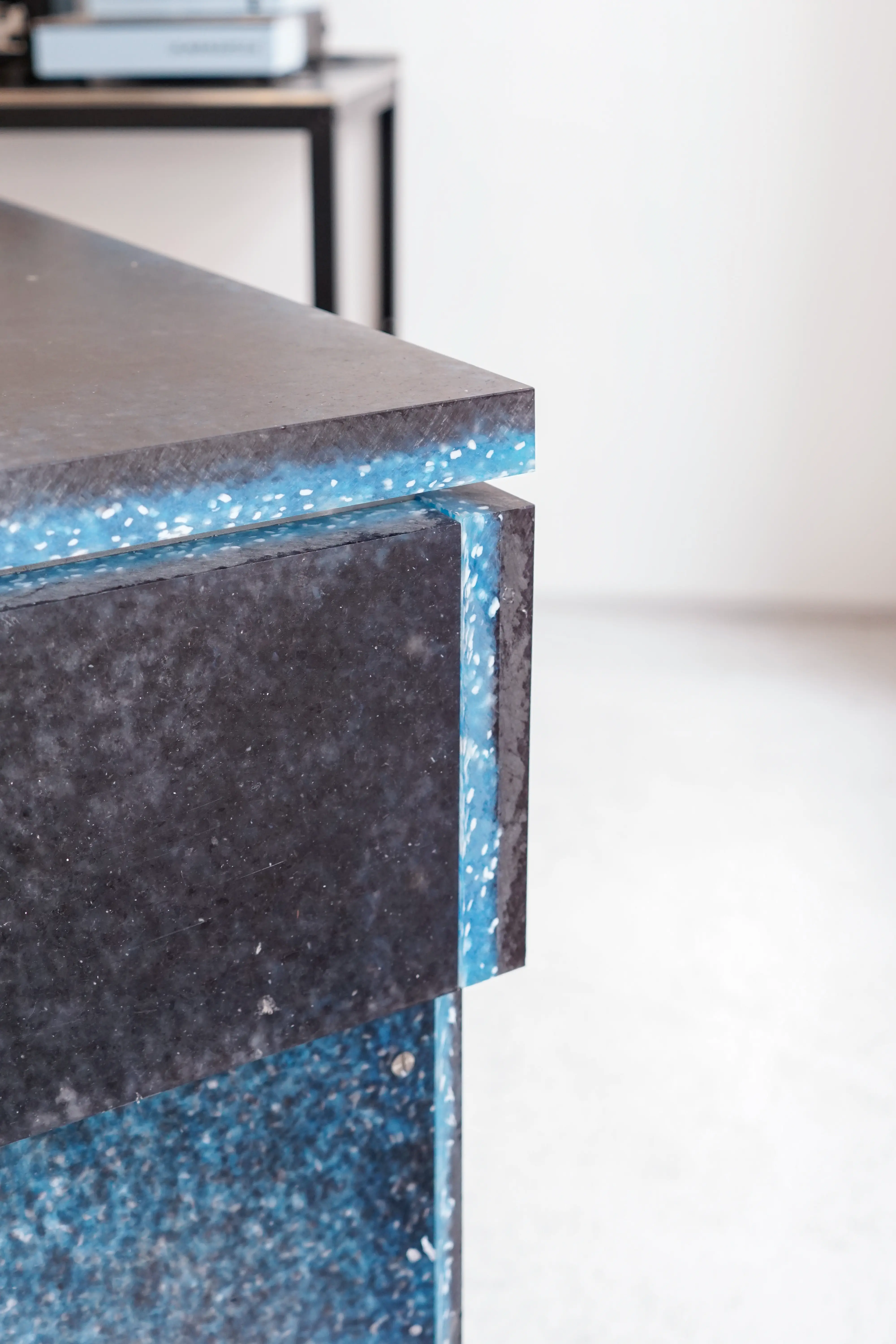

Laurent When we set foot in the space for the first time it was basically a construction site. It nevertheless gave us good energy because we saw a room with a lot of potential. Around that time, you guys had just moved into your workspace. We came by to see more samples. I was like, Okay, there's translucency—that's pulling me in. This is what I want. I felt like no other coffee place had this aesthetic. We were interested in the Nu Amber design at first—a brown base with colored sprinkles. I grew up in the mountains and loved the idea of the source material being shields from ski lifts. After that visit, we brought the samples to the space and lined them up in the middle of the room. We started excluding things: black was too dark, taking too much brightness away. Brown reminded us of vintage brass furniture and we had to exclude it too as was not really what we were searching for. And then there was the blue—which nobody really wanted. But then we sandwiched two samples together: two samples of a Mirage and a Marin. We thought, why not layer them so there's a darker and a brighter side? We immediately got very excited. We had to pitch this to you and see if it would be technically possible! In my head, it would be as easy as producing two separate plates and heating them together until they melt into each other. So when Peter told me you have to do this by hand and that you were going to make samples for us, I immediately thought, "Fuck, it's gonna turn out blue." I came alone to pick up the first sample. When I saw it, I went, "Oh shit, that's my bar right there."

Capeland It was a really fun part of the project. You were so enthusiastic about working with us on this special material request. Both Raphael and Julian were eager to try everything possible to accommodate our request. We needed to make a couple more samples to adjust the amount of transparency we wanted, but we eventually got there!

Laurent At that point, I had a logo and a name, but no corporate identity or color scheme in mind. And all of a sudden, it was right in front of my eyes and in my hands. I was seeing it everywhere. I changed my Instagram profile picture to blue and instantly got a text from Camilla. She never texted me. I like the blue.

So many things come perfectly together.

Laurent The first version of the bar featured 30 millimeters panels only. All over. And I thought I’d need three years to pay that. So I shortly panicked and thought maybe we should go for wood after all, and implement the plastic panels later. And both Peter and Camilla were like if we don't do this now, it's never gonna happen. Then we started to calculate and plan on where we could actually make use of thinner plates for the walling of the steel modules for example, and come back to a budget I could see myself investing. We calculated everything so that we would make use of every inch of material we ordered.

This means all these details—like the small gaps between the bar top and the sides—are intentional. And that thicker stripe of the walling... also deliberate because it's what's left over from the large piece. It makes sense and is very satisfying too that you can argue for that. Seems like the negative space within the construction has actually contributed to a big save in costs and excess in material.

Laurent The hardest part was obviously the drilling and assembling. This was quite painful because wood allows you for mistakes, you can always cover up holes or fill them back. Also there is always some tolerance in the thickness between each produced plate meaning we had to be carefully matching all pieces before mounting them to be sure they would fit well together, gladly you had delivered them to us mostly marked already which was a great help. Not all parts are perfectly matching and you could even find some disturbing details if you look at each specifically, but if you look at the whole bar, you don't realize anything. And anyway if you really see the process behind it, you cannot make it better because with wood, something like this happens, but you take a sander and you just make it plain true. If you make this with that, it just doesn't work like that.

We had been testing with different materials, temperatures, and mixing techniques for over a year before getting this project commissioned, but BEANDEPENDENT was the first we have ever billed as FANTOPLAST.

We had moved just for a few months in our new workspace and hadn't pressed any three-centimeter panels, not even for testing. We had the forms but never built them because we didn't need to. Testing would have required a lot of material and we had postponed it in favor of other thicknesses we would need to produce projects that were in the pipeline. So we waited until we actually needed to test.

I think that the first time we made a three-centimeter prototype in the small press was exactly the prototype for the bar. There was a lot of tension in the workshop those days. When I hear your side of the story, everything sounds much nicer than I remember. It wasn't because it was bad—it's just that you're under a different kind of pressure, right? It's interesting to hear how you came up with the idea of merging the colors. I remember this as a third-person impression from someone not actively working in production. I'm aware of everything happening, but I'm less emotionally involved. When something goes wrong, I see what's wrong. Maybe it's annoying for my colleagues sometimes when I say, "Oh, that's bad," and people are going crazy. But that's how it is somehow…

Laurent Honestly, I enjoyed the whole process. Raphael, who was our contact person for the project, gave us a lot of confidence, always checked back with Julian to see if what we were asking for was actually feasible and technically possible. Julian was equally confident, so we never had the feeling we were pushing any boundaries. Raphael made us aware that the dark materials, especially on the surface, could be more susceptible to scratches. I instantly thought that there are only so many places where scratching could happen because most of the surface has things stored on top—cups, plates, the machines themselves—which are not ever going to be moved and cause scratching. No matter what material you use, there will be signs of usage over time. I appreciate simplicity and minimalism, but I allow for errors and natural signs that something happened here. This is really nice. And after more than a year, there aren't even that many scratches.

We do not have any of this material anymore. We have the designs in our collection but the source material is different, meaning that also the color has somewhat changed from that first batch we had. So you better, you better keep them entirely without breaking them because there's no replacement.

Laurent In the beginning, so many people asked about it. They liked the design and wanted to know who made it, what it was, and how. I always told them the whole story—that it's a design from Capeland and me, with panels from FANTOPLAST. I was sometimes scared someone would copy it, but I felt confident that you guys wouldn’t resell the design that had come out specifically for the project.

It would still look quite different, even if we tried! We are still very happy about the project. Of course we have two more years of experience now, which we lacked back then. We have a different way of treating the surface to obtain a nice grainy texture. It never happened again to merge two designs in one! Are you still happy about the project?

Laurent I am! I am still very excited about it every single day, because the day light (and how it develops during the day) constantly changes my impression of the bar. Different parts of the bar light up throughout the day according to the time of day. The first summer I spent here, I turned around, all of a sudden the bar started glowing blue and all, and I was like, what the hell…

I really like that the place has a certain 'technical' vibe, as opposed to cafés with warm colours and interiors. It's cold here, but in a way that makes it an enjoyable place to be.

Laurent In the end, I didn't ask them to plan or create a bar for me. I asked them to build a stage for me and my coffee, and the coffees that are presented here. It shouldn't be so fancy that it takes away from the experience of the coffee. That's why I don't have anything else going on in my room because the center product is my coffee and I don't want to have anything else like fishing away from the focus on the coffee moment.

This project was a creative collaboration through and through. And I really appreciate it. Every day I sit on that bench, I look inside the bar – it's the best spot really – you look at it, you see the blue side more than the dark side, and all of a sudden the whole thing changes.

And you made peace with the blue?

Laurent My whole whole vibe is blue. My daughter’s favorite color is blue. And she talks about how she has a café that is blue.

Links

BEANDEPENDENT

Lessinggasse 19, 1020 Vienna

capeland – Büro für Raum und Gestaltung

Sulmgasse 11/ 1—01A, 1160 Wien

Cover Image: BEANDEPENDENT bar view © FANTOPLAST